Description

– A PCB Welding Terminal Connector is a type of connector used to establish a secure and reliable electrical connection between wires and a printed circuit board (PCB).

– These connectors are designed to be soldered directly onto the PCB, providing a robust and permanent attachment point for wires.

– They are commonly used to connect external components or other PCBs to the main board, facilitating the flow of signals or power

Key Features:

Function:

Secure Connection:

Welding terminals provide a strong, reliable connection between wires and the PCB, minimizing the risk of loose or damaged connections.

Signal/Power Transfer:

They enable the transfer of electrical signals or power between the PCB and external devices or other PCBs.

Permanent Mounting:

Unlike some other connector types, welding terminals are designed for a permanent attachment to the PCB, making them suitable for applications where a secure, long-lasting connection is essential.

Types:

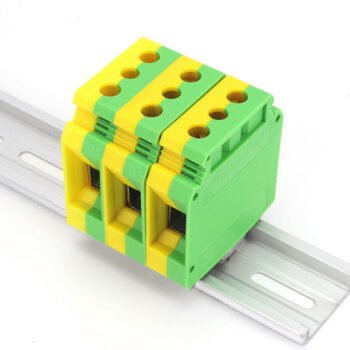

Screw Terminals:

These terminals use screws to clamp down on the wire, providing a secure connection. They are often used for higher current applications and can be found in various configurations (e.g., single-level, dual-level).

Spring Terminals:

These terminals utilize spring-loaded mechanisms to hold the wire in place, offering a quick and tool-free connection method.

Pin Terminals:

These are simple terminals that provide a direct connection point for wires to be soldered onto the PCB.

Ring Terminals:

Ring terminals are designed to be crimped onto a wire and then screwed down to the PCB.

Fork Terminals (Spade Terminals):

Similar to ring terminals, but with a fork-shaped end for screw attachment.

Reviews

There are no reviews yet.